Selective Laser Sintering (SLS): Advancing Additive Manufacturing Capabilities

- Mir Misbah Ali

- 10 Jun 2023

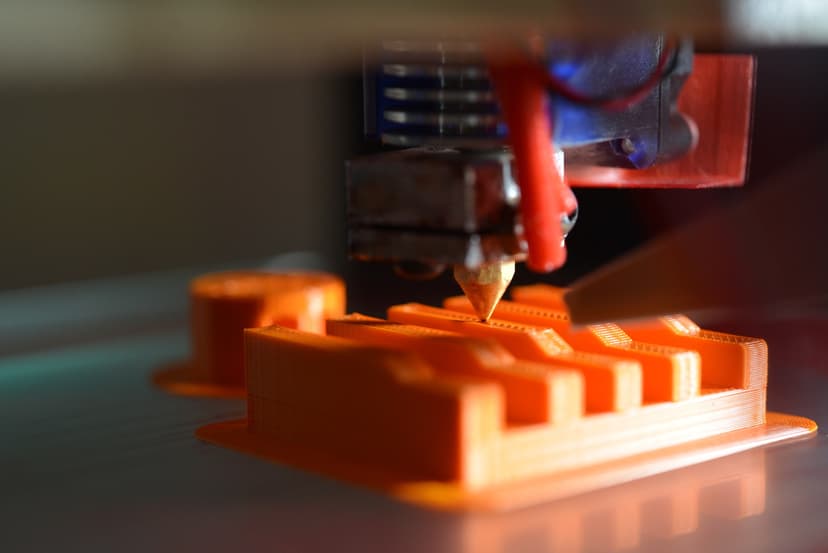

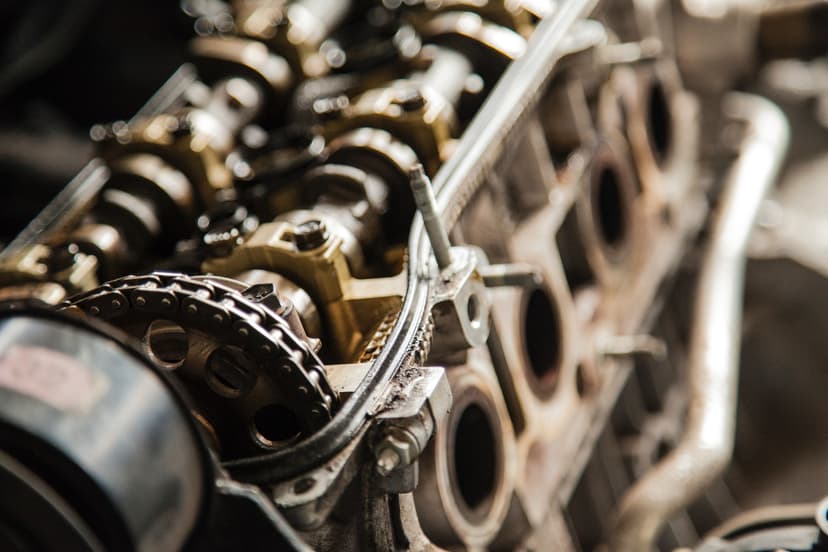

> Selective Laser Sintering (SLS) is an additive manufacturing process that utilizes a high-powered laser to selectively fuse powdered materials, such as thermoplastics or metal powders, to create thr

Read More