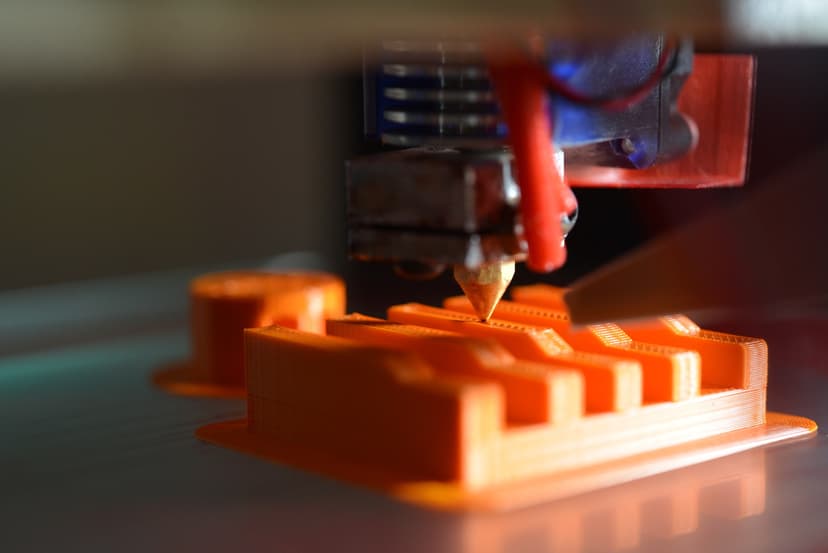

Selective Laser Sintering (SLS) is an additive manufacturing process that utilizes a high-powered laser to selectively fuse powdered materials, such as thermoplastics or metal powders, to create three-dimensional objects layer by layer.

The SLS process involves the following steps:

- An even layer of powdered material, such as nylon or metal, is spread across the build platform.

- A high-powered laser scans the digital model's cross-section onto the powdered bed, selectively sintering or fusing the powder particles according to the model's specifications.

- After each layer is scanned and sintered, a new layer of fresh powder is applied, and the process repeats. The build platform gradually moves downward, and the laser continues to sinter each layer until the object is complete.

- The finished object cools down within the powder bed to maintain its shape and structural integrity.

- The printed object is carefully extracted from the powder bed. Excess powder is cleaned off, and the remaining powder can be reused, minimizing material waste.

- Additional steps, such as support structure removal, surface finishing, or polishing, may be performed based on the desired outcome.

Advantages of SLS include:

- Material Versatility: SLS can work with various materials, including plastics, metals, ceramics, and composites, expanding its potential applications.

- Support-Free Printing: The unsintered powder acts as its own support, eliminating the need for additional support structures during the printing process.

- Complex Geometries: SLS can produce objects with intricate designs, internal cavities, undercuts, and complex geometries, without requiring assembly.

- High Strength and Durability: SLS prints often exhibit excellent mechanical properties, making them suitable for functional parts and end-use applications.

- Material Reusability: The unsintered powder can be reused in subsequent printing jobs, reducing material waste and cost.

Disadvantages of SLS include:

- Post-Processing Requirements: Additional steps, such as removing excess powder, may be necessary to achieve the desired surface finish.

- Resolution Limitations: SLS may have constraints in achieving high levels of detail and surface smoothness compared to other additive manufacturing processes.

- Equipment Cost: SLS machines and the required high-powered lasers can be expensive, making it more suitable for industrial applications.

Applications of SLS encompass various industries:

- Functional Prototypes: SLS is widely used for creating functional prototypes in automotive, aerospace, and consumer goods industries.

- End-Use Parts: SLS is suitable for manufacturing customized and low-volume production parts, particularly when strength and durability are crucial.

- Tooling and Jigs: SLS produces tooling components like molds and jigs for various manufacturing processes.

- Medical Applications: SLS finds use in producing patient-specific implants, surgical guides, and anatomical models in the medical field.

- Complex Geometries: SLS enables the production of intricate architectural models, artistic sculptures, and complex designs that are challenging to achieve using traditional manufacturing methods.

Selective Laser Sintering (SLS) expands the capabilities of additive manufacturing by offering material versatility, complex geometry production, and the ability to create functional prototypes and end-use parts with high strength and durability. It finds applications across industries such as automotive, aerospace, medical, and art.